Value Engineering in Action: How HJYLED Delivered a Cost-Effective LED Display in 72 Hours

Meta Description: Tight budget and urgent deadline? See how HJYLED used steel cabinets and streamlined processes to deliver a fully functional LED display with 3-day production & shipping.

In commercial projects, the most formidable obstacles are often twofold. “Limited budget” and “tight deadline” can seem like insurmountable barriers for businesses needing an LED display. Does the client have to compromise on quality or miss their critical timeline? At HJYLED, our answer is a definitive no. We specialize in delivering significant cost savings while achieving what many consider impossible lead times.

Our client, an expanding fitness chain preparing for its grand opening, faced this exact “dual dilemma.” They needed reliable indoor LED displays for class schedules and promotional content across multiple locations.

-

Challenge One: Extreme Budget Constraints. The project had very tight financial limitations.

-

Challenge Two: Aggressive Timeline. The window from order confirmation to shipment was a mere 72 hours, far shorter than standard industry lead times.

This meant we had to engineer a high-value solution that was not only cost-effective but also executable at an unprecedented speed.

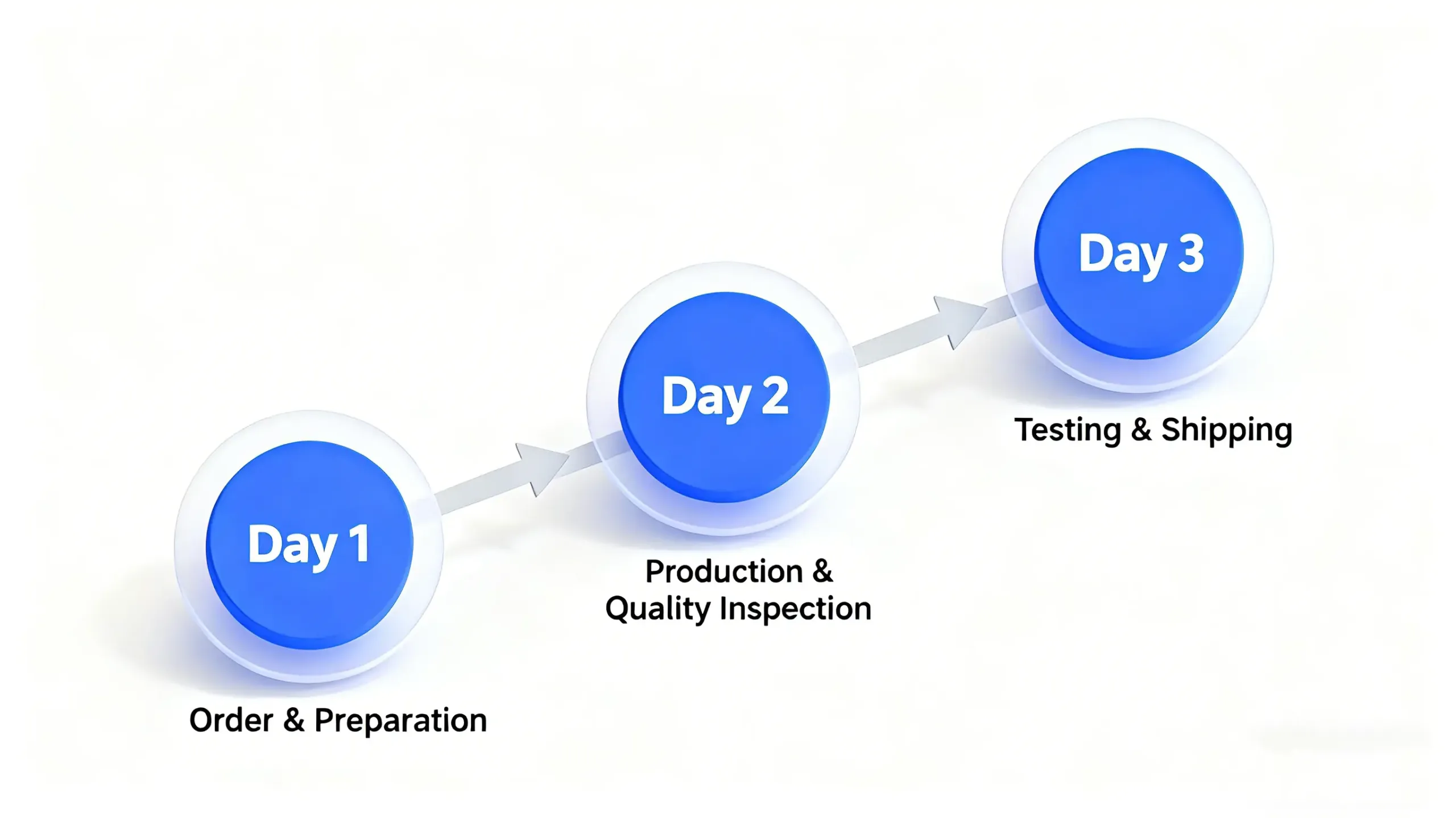

Faced with this challenge, our team activated a “rapid-response” protocol, deploying a dual-strategy solution:

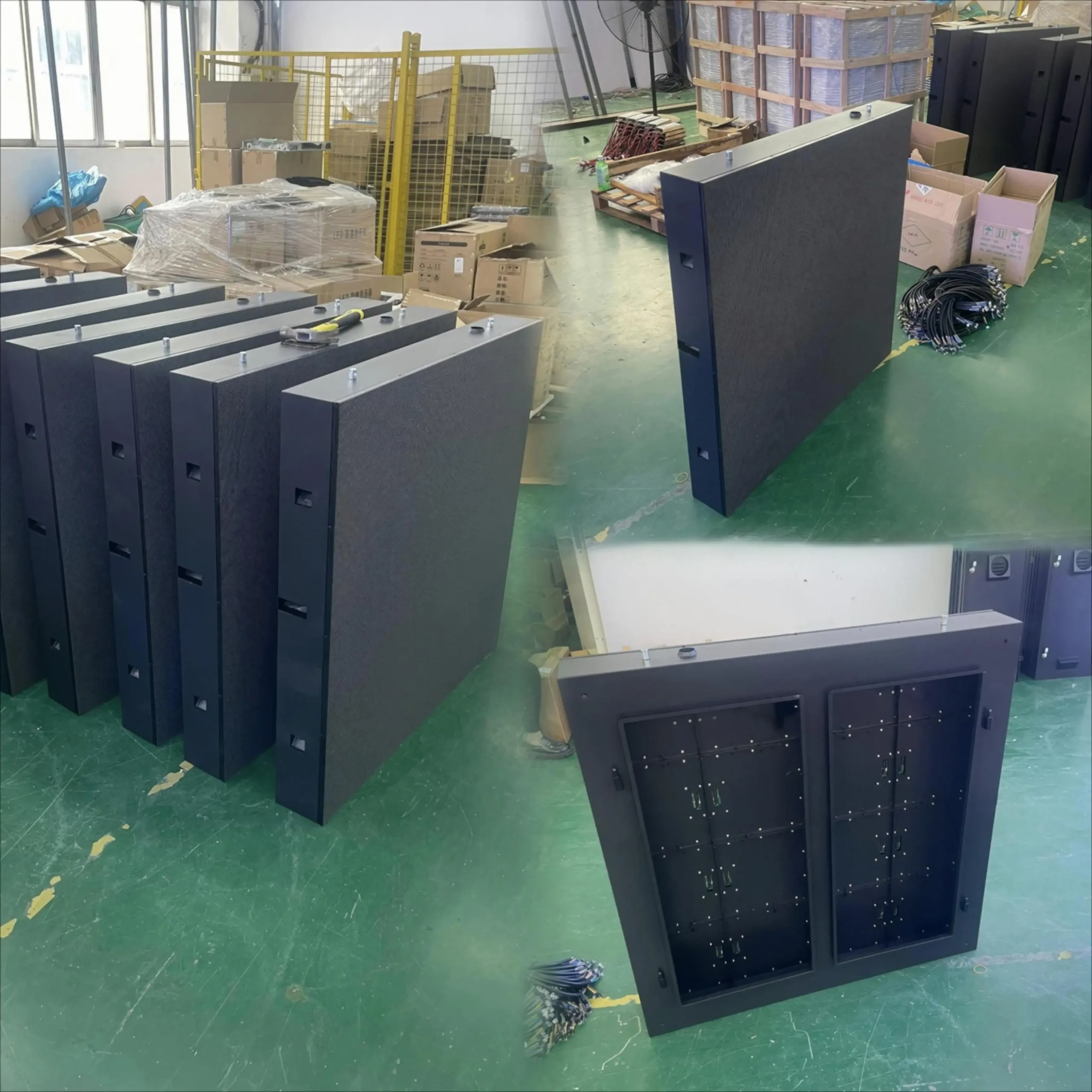

1. Cost-Optimization: The Strategic Cabinet Material Selection

Our core engineering decision was to replace traditional die-cast aluminum cabinets with high-value, structurally sound steel cabinets. This pivotal move maintained the necessary rigidity and durability for indoor use while reducing core material costs by nearly 50%, making the project financially viable.

2. Speed & Efficiency: Streamlined Production and Process Optimization

-

Standardized Components: The recommended steel cabinets and associated modules were part of our highly standardized inventory, eliminating the need for custom tooling or long-lead-time parts.

-

Streamlined Assembly Line: Our production, assembly, and QA teams worked in a seamless, parallel workflow, drastically compressing processes that typically take days.

-

Precision Time Management: From the moment of order confirmation, every operation was scheduled down to the hour to ensure zero delays.

From order receipt to final production, assembly, quality testing, and packing for shipment, the entire process was completed in just 72 hours, delivering the custom-built HJYLED Value S-Series indoor LED display.

The success of this project exceeded the client’s expectations on both fronts. They acquired a high-performance display at a fraction of the expected cost and resolved their critical path issue for the grand opening.

“HJYLED’s performance was exceptional,” the client stated. “Their professional recommendation to use steel cabinets was a game-changer for our budget. But what truly amazed us was the 3-day turnaround from order to shipment. This was decisive for our launch timeline. HJYLED is a partner you can trust.”

This case study proves that high value and high velocity are not mutually exclusive. This achievement is built on HJYLED’s robust supply chain management, highly standardized product ecosystem, and superior project execution.

At HJYLED, we are redefining client service standards. We are not just an LED display manufacturer; we are your trusted partner for mission-critical visual solutions. Whether you face budget constraints or urgent deadlines, we have the expertise and capability to deliver a perfectly balanced answer.